The body of traditional wood-burning stoves is made of cast iron. This is an extremely strong and durable material but sometimes you will start to see cracks on the outer surface (or even the inside) of the body. When you consider the strength of cast iron it needs to be under huge pressure to crack. So, why has your wood-burning stove cracked and what can you do about it?

Flue pipe is not supported

Even though the body of a wood-burning stove is made from seriously durable material it is not designed to be load-bearing. A correctly structured flue system does not place undue pressure on the stove and would not normally lead to cracking. Unfortunately, we have seen situations where a flue system is not structured correctly and is indeed load-bearing on the body of your stove.

Due to the different characteristics of cast iron, the body of your stove, and the steel used with flue systems, they expand and contract at different temperatures. As the stove body is exposed to the greatest temperatures the cast-iron will expand more than the flue system. This in turn can create significant pressures on the flue collar and ultimately lead to fracturing. Once fracturing has occurred it is very difficult to repair although it will depend upon the area which has begun to fracture and how quickly it was recognised.

Over firing your stove

Considering the durability of cast iron, many people may be surprised to learn that you can actually over fire your stove. This effectively means that the inner stove workings are exposed to temperatures much higher than what they were designed for. As the inner part of the stove heats up much quicker than the outside, this can cause pressure which can ultimately lead to cracking. So, how could your stove be exposed to over firing?

The simplest reason for over firing is the introduction of excess air which feeds the flames and increases the temperature. As the air inlets are controllable it would be no surprise to learn that very often disintegrated rope seals leave gaps in the stove door through which air is sucked. This air then feeds the flames, increases the temperature with over firing causing major problems for not only the body of the stove but also efficiency. Check your door seals on a regular basis!

Too much fuel is dangerous

Again, many people fail to comprehend that even the most durable of cast-iron bodies are not designed to withstand heat above and beyond traditional stove temperatures. The simplest way to over fire your stove is to pile fuel on top of fuel or use the wrong type of fuel. This can create hotspots, intense heat which will eventually crack the inner workings/outer workings of your stove body. As you become more experienced with your wood-burning stove you will begin to appreciate the amount of fuel that should be taken on board.

The simplest way to ensure that you do not use too much fuel is to add a flue pipe thermometer to your system. If you take a look at your manufacturers guide it will show you the “optimum” temperature at which your stove is most efficient and creating safe heat. If the flue pipe thermometer goes over this temperature then you need to reduce the fuel. On the flipside, if the temperature is well below the optimum level then it might be an idea to add a little more fuel until you get to the manufacturers guide temperature.

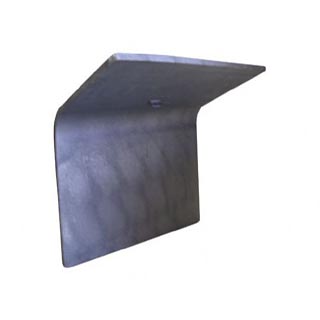

Damage baffle plate

The role of the baffle plate is to ensure that the flames and heat created in your wood-burning stove are spread evenly across the surface of the inner stove. This helps avoid the creation of heat spots which can emerge near the flue collar if the baffle plate was damaged. As a result of intense heat on a very specific area of your stove, at some point the material will come under pressure and eventually crack. It is therefore imperative that you check your baffle plate on a regular basis because this also ensures efficient heat generation and will save you fuel in the longer term.

Even though the baffle plate is an integral part of the modern day wood-burning stove, and has been for many years, it is very simple to replace. Spare parts will be readily available through stove retailers with a simple step-by-step guide to removing the old baffle plate and installing the new one. Simple!

Conclusion

The idea that a solid wood-burning stove with a cast-iron body may be susceptible to cracking is alien to many people. Those with limited experience of using wood-burning stoves seem to automatically assume it is simply a case of piling as much fuel as possible into the body of your stove. Despite the fact they may look cumbersome, solid and durable; the design of any wood-burning stove is specific to an optimum temperature. In many ways the beauty of the modern day wood-burning stove is its traditional look and traditional feel despite the fact it is designed for optimum performance.

Simple issues such as over fuelling your stove or allowing too much air into the combustion chamber will ultimately bring about its premature demise. So, when you carry out your annual or biannual inspection, make sure you check the flue system, check any damage inside the stove and any indications of external cracks emerging.